Resprayed the timing chain cover and fitted it with new gasket and oil seal.

New alternator mounting bolt.

After fitting all missing items to make engine mountings work again. Resprayed the engine mounting bracket on radiator side etc.

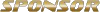

Ready to be dropped in....

AND THE ENGINE HAS LANDED AND IS BACK...well sort of...

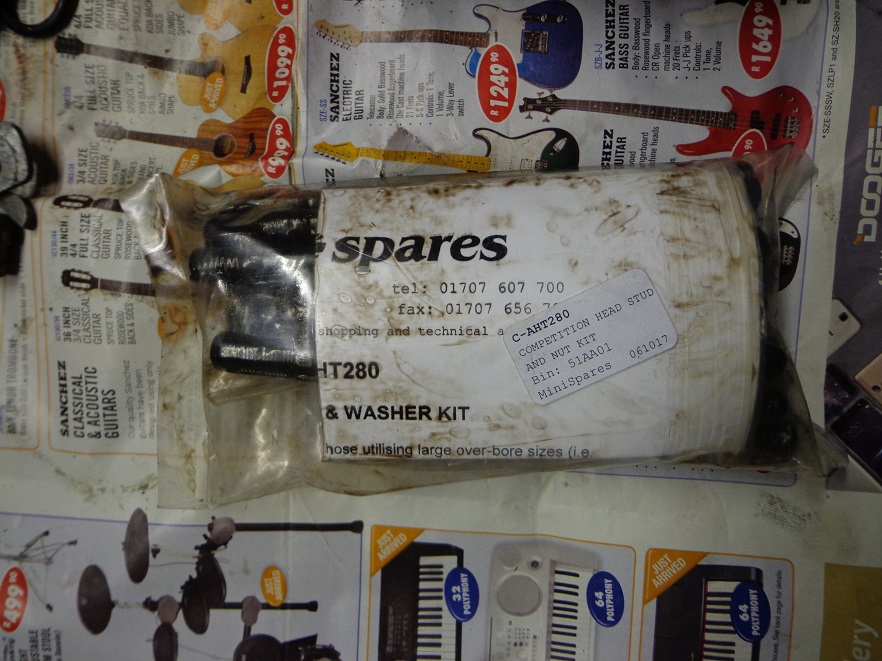

Had to build the head next...

Cleaned these babies up.

Then new valve stem seals was fitted and new kent cams double valve springs.

New head stud kit to fit head.

Here things got interesting.. the kit only comes with 5 thick washers and 2 thinner washers for the two studs on the very ends... The four long studs has no washers, did a lot of research and found that is how this kit comes, so that is how I fitted it.

Built up a adjustable top engine steady.

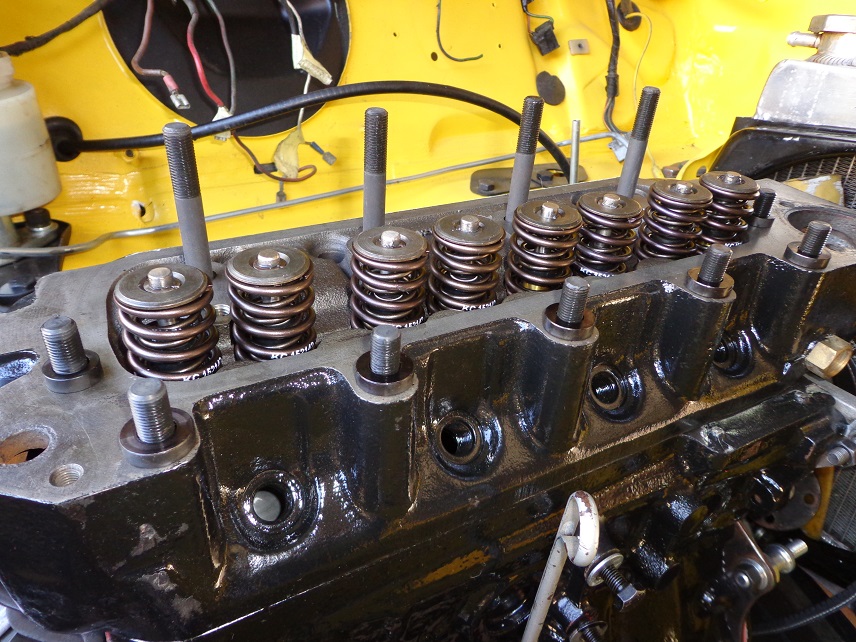

Studs and gasket fitted, awaiting head.

See washers fitted onto studs....

Own some minis, break them, fix them, improve them, test them to the limit....

![[-]](https://samini.co.za/images/collapse.png)