Posts: 271

Threads: 28

Likes Received: 90 in 61 posts

Likes Given: 0

Joined: Aug 2015

Reputation:

2

08-21-2020, 06:52 AM

(This post was last modified: 08-23-2020, 06:22 AM by GTSPhil.)

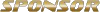

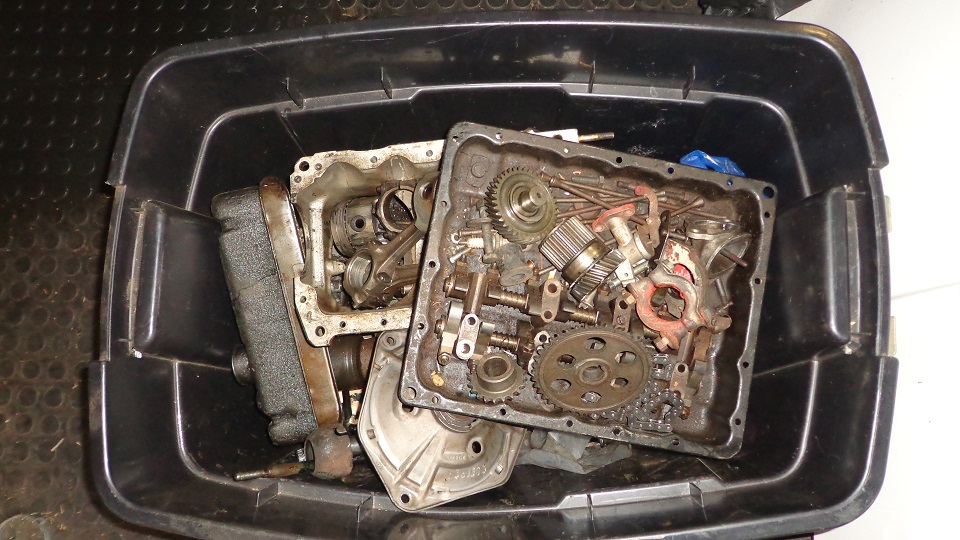

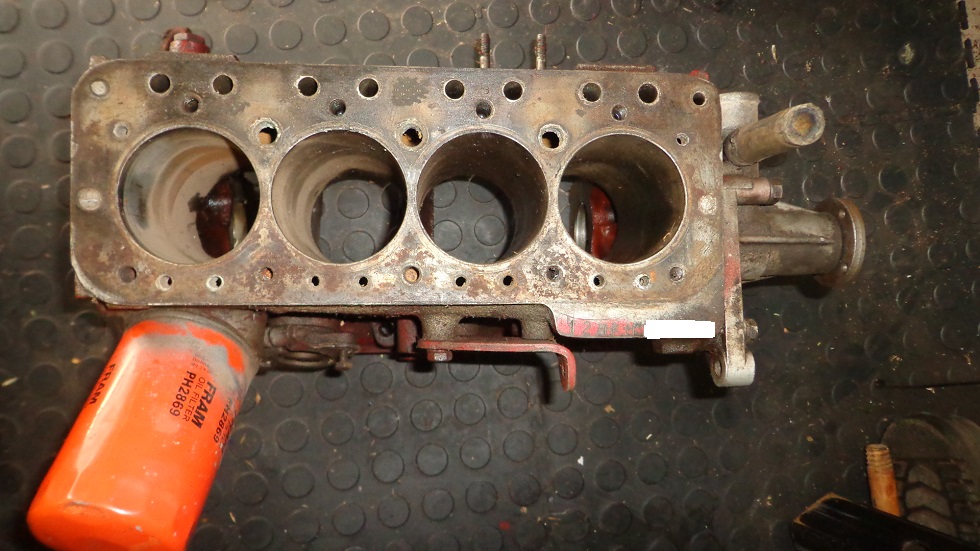

I started with this bundle of joy.

And

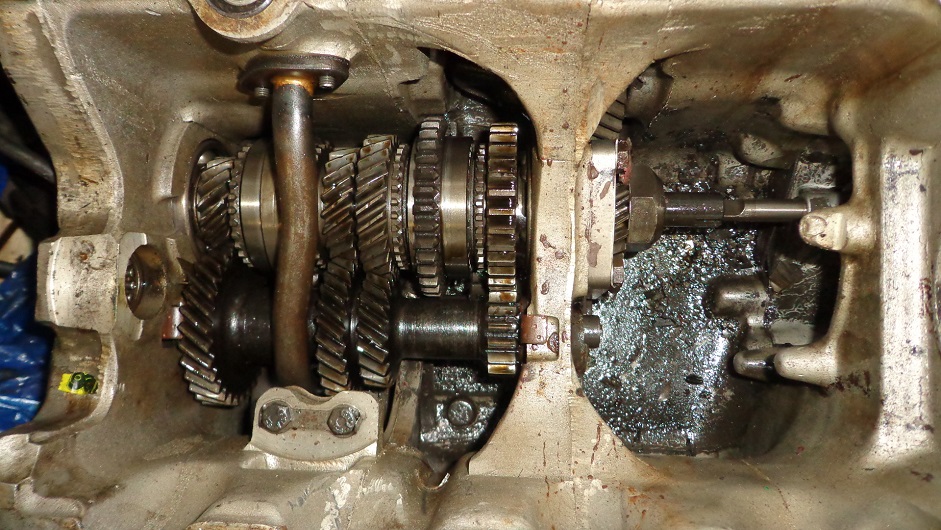

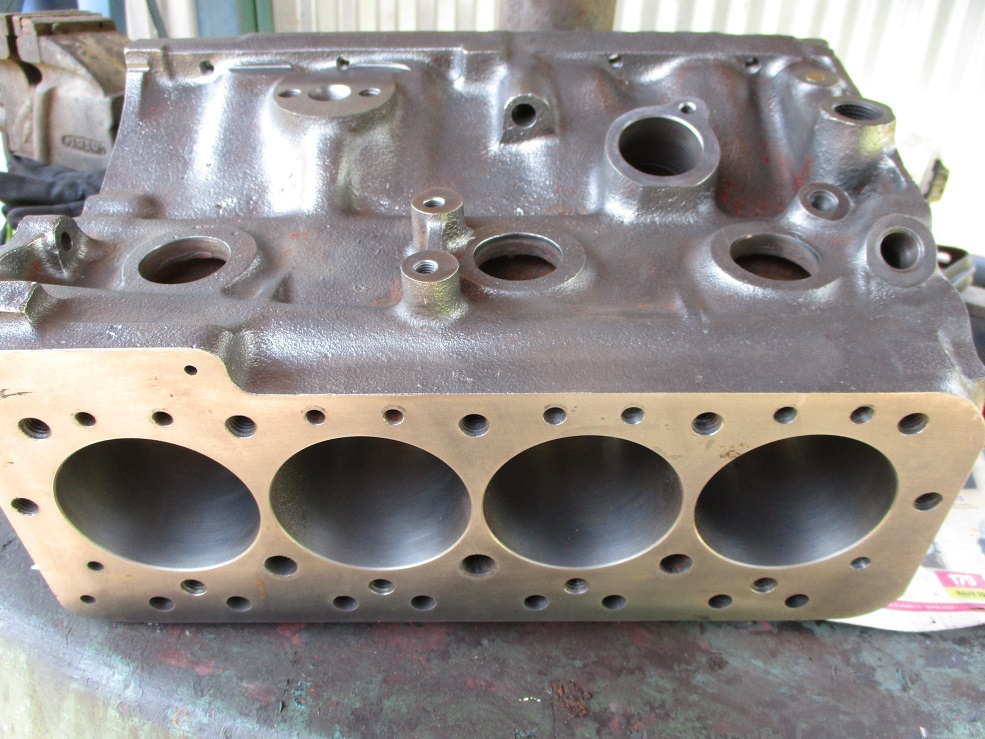

the engine block

As per normal a trip to the engineering shop and some new Nural 40 thou goodness later....

I think I have found why this poor E engine had failed, and it was not "a slight problem" as per the previous owner had down played the state of the engine.

After a few rounds of pressure washing, pressure sprayed parafin and some degreaser, ah much better.....

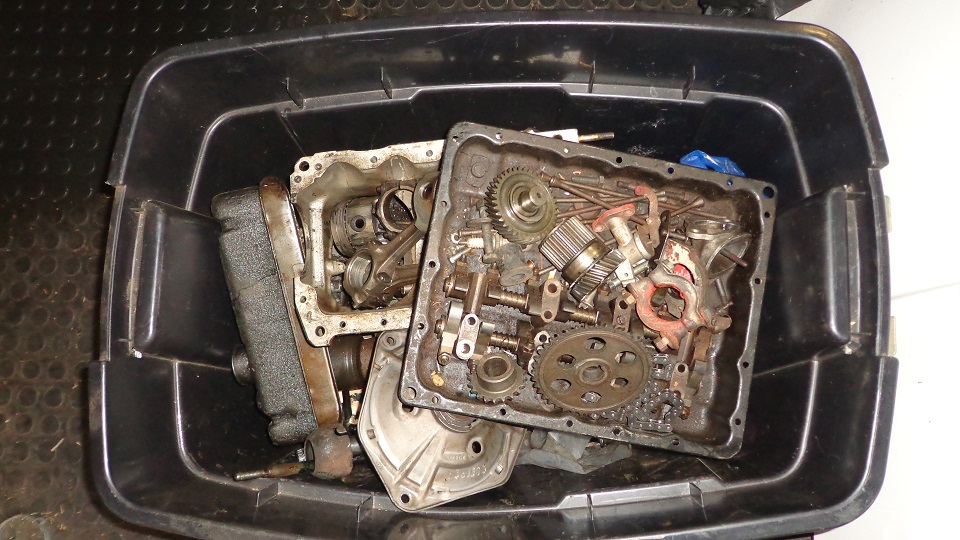

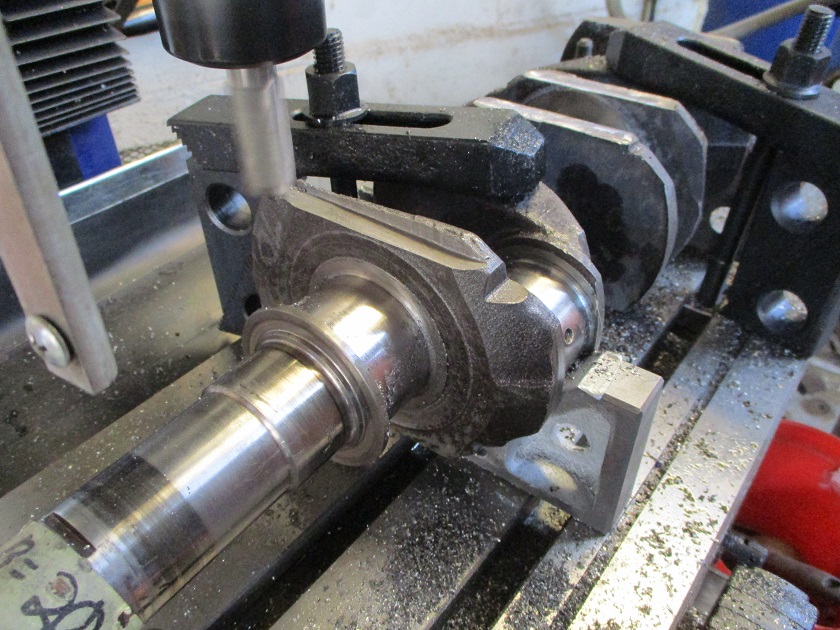

Gearbox mainshaft getting some much needed new bearings and baulk rings.

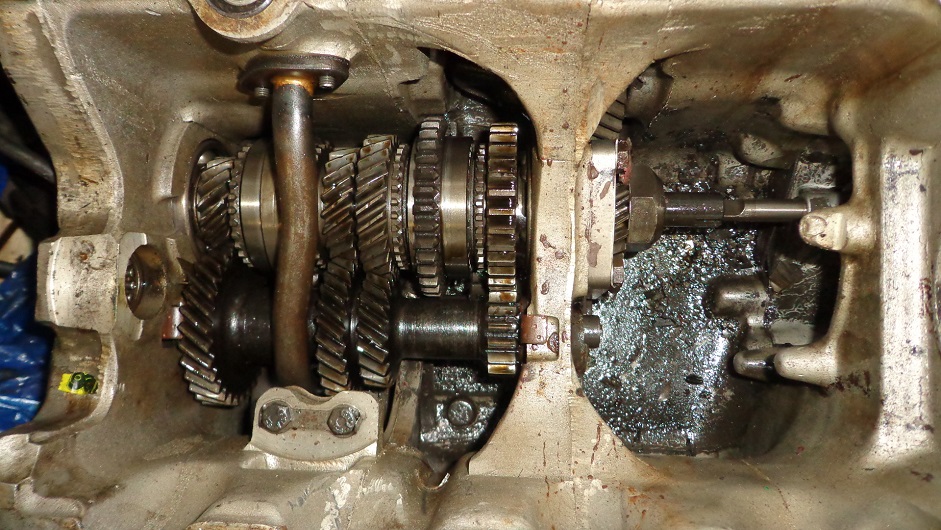

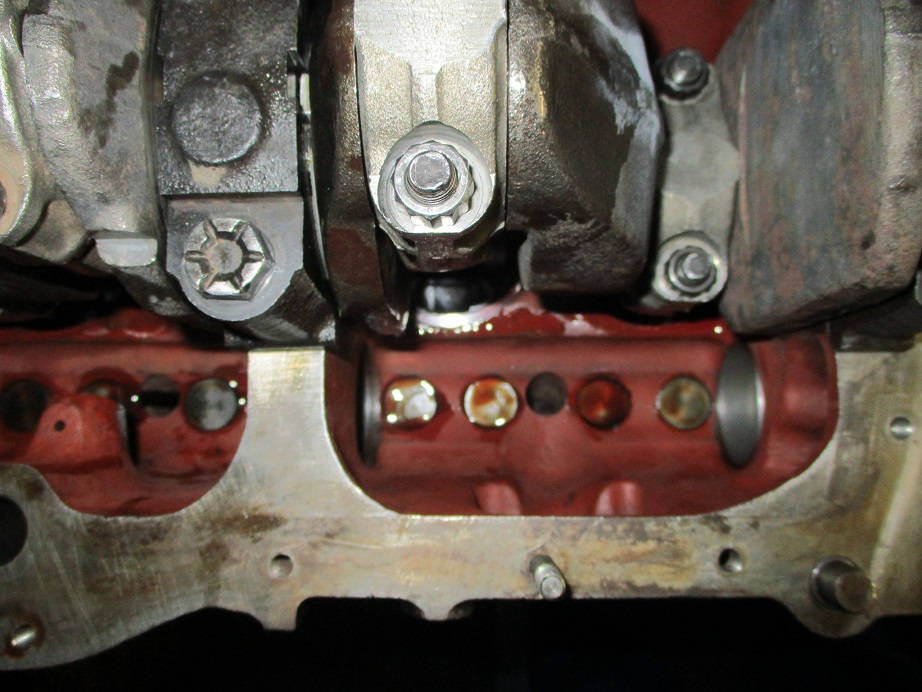

Gearbox fully rebuilt and shimming of the idler gear.

New cam followers, bearings, thrust washers and pistons later.....

New oil pump

Fixing threads on back plate.

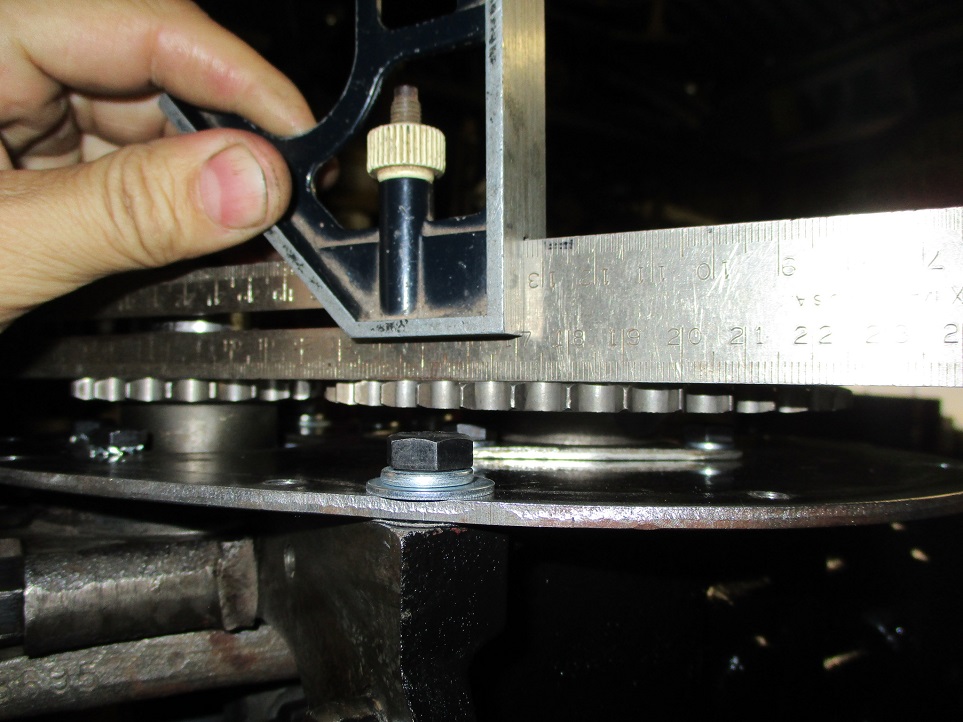

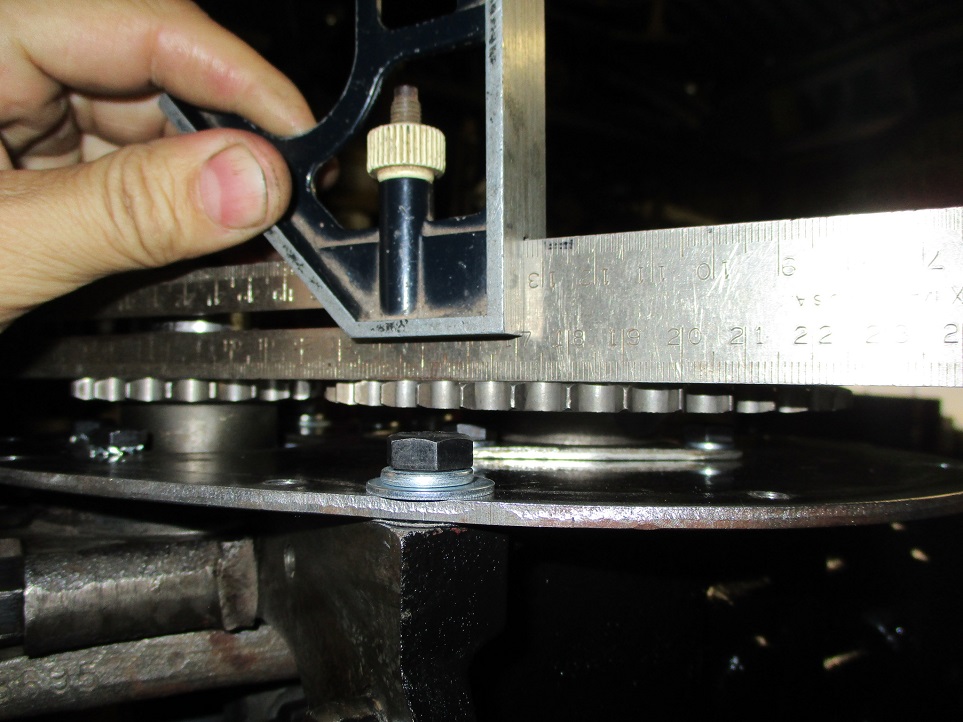

Checking timing gears for alignment.

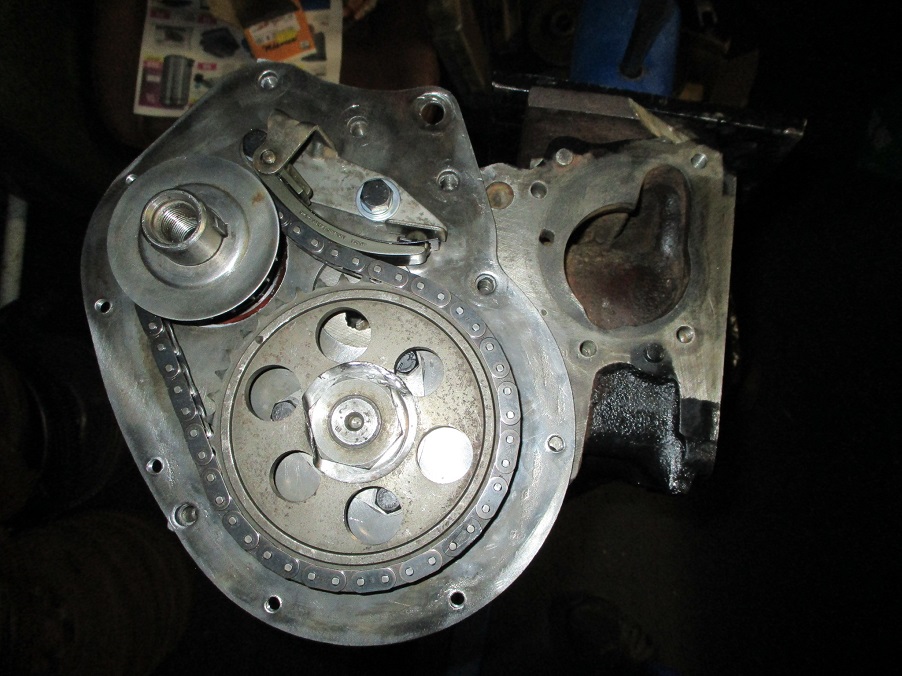

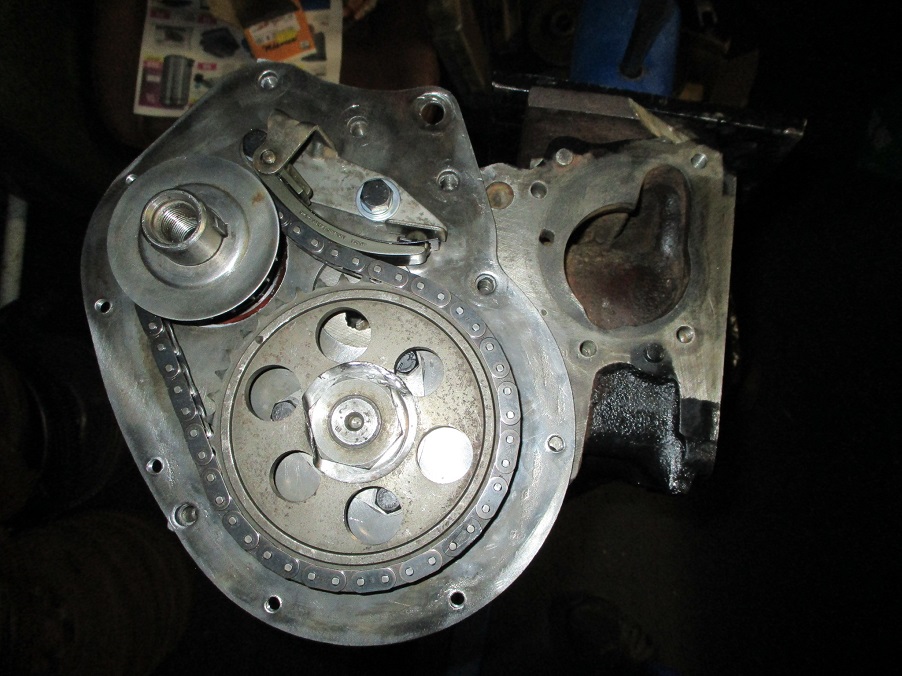

New chain and tensioner later.

Starting to look like an engine again.

Reconned the rocker cover and finally...

Own some minis, break them, fix them, improve them, test them to the limit....

Posts: 271

Threads: 28

Likes Received: 90 in 61 posts

Likes Given: 0

Joined: Aug 2015

Reputation:

2

08-23-2020, 08:20 AM

(This post was last modified: 08-24-2020, 06:40 PM by GTSPhil.)

Lifting out the GTS engine, which I seem to be doing once or twice a year....

I needed the clutch assembly, dizzy, alternator and starter etc for E engine.

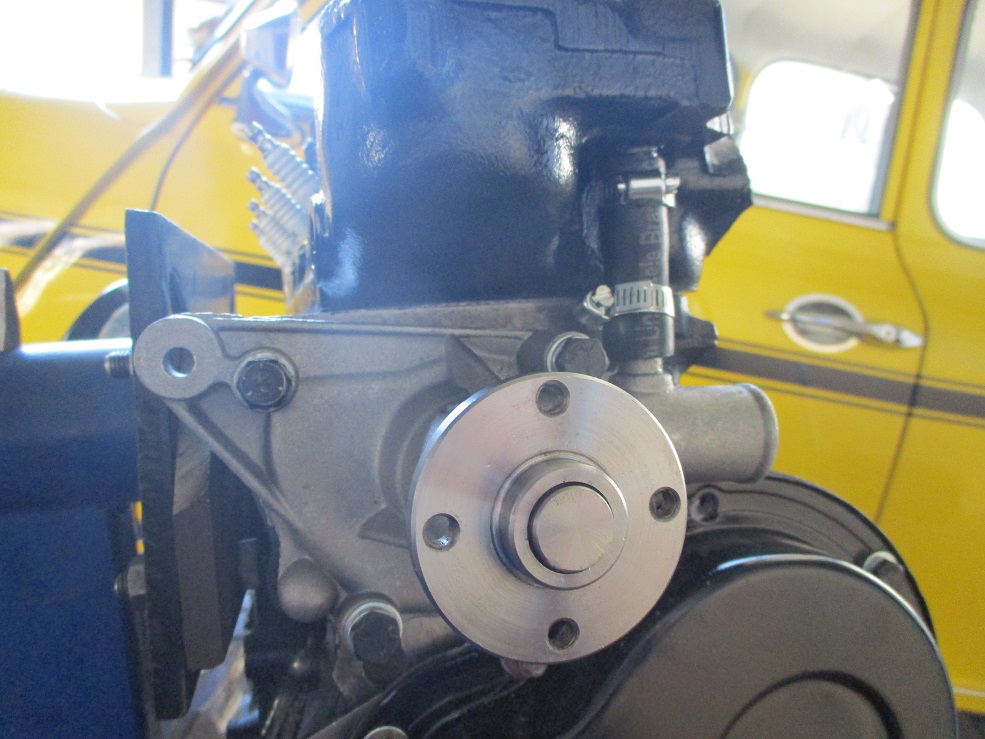

Fitting new water pump to E engine.

Had to repair some radiator cowlings as I did not want to run the all alloy radiator and one piece cowling. This was quite a nice job, since previous owners just cut the cowlings for no good reason, WHY......

Own some minis, break them, fix them, improve them, test them to the limit....

![[-]](https://samini.co.za/images/collapse.png) •

•

Posts: 271

Threads: 28

Likes Received: 90 in 61 posts

Likes Given: 0

Joined: Aug 2015

Reputation:

2

Had to press in a new steady rod bush.

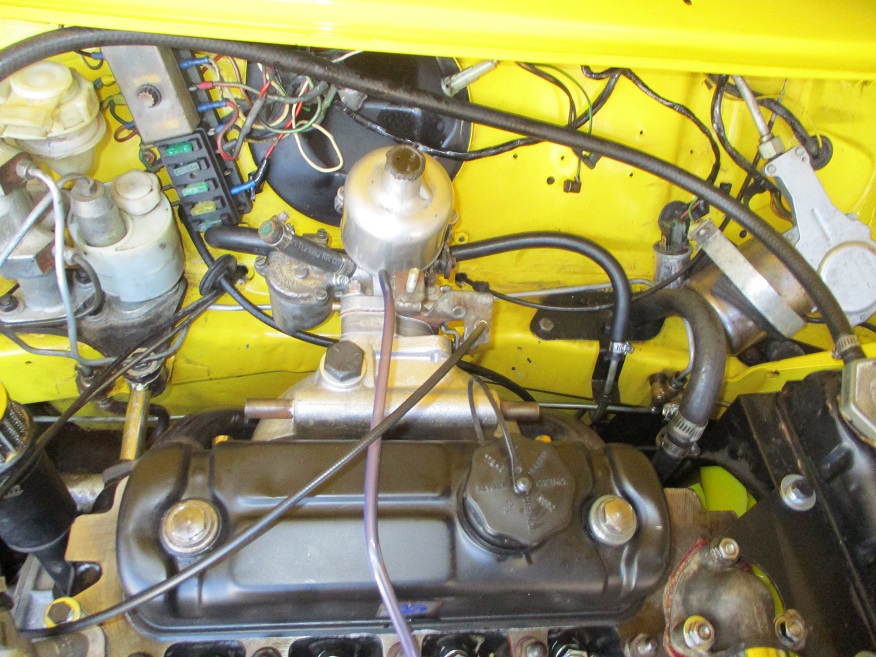

All installed and ready to rumble.

Own some minis, break them, fix them, improve them, test them to the limit....

![[-]](https://samini.co.za/images/collapse.png) •

•

Posts: 271

Threads: 28

Likes Received: 90 in 61 posts

Likes Given: 0

Joined: Aug 2015

Reputation:

2

Next up I had enough of the front bumper shaking and vibrating, so I needed some bushes between the body and mounting bracket, tie bar bushes was too big. I found something smaller that worked like a charm.

Nice and secure.

I then decided to run the car and E engine on a single carb, I needed a new alloy inlet as I did not have anymore standard cut-off items to use.

I then just built a HS4 that I had laying around.

Own some minis, break them, fix them, improve them, test them to the limit....

Posts: 271

Threads: 28

Likes Received: 90 in 61 posts

Likes Given: 0

Joined: Aug 2015

Reputation:

2

Now back to the original GTS engine. I think the problem have become clear again....

And bye bye copper head gasket.

It has been established that my beautifully modified cylinderhead on this engine has cracked further between no 2 and 3 combustion chamber from the brass plug towards the centre of the head......INSERT CHOICE SWEAR WORDS HERE........

So after replacing a few head gaskets and still having low compression, I decided to start completely afresh back to the drawing board. Since the 1275E engine that is currently fitted is a spare engine that will be sold, the hunt for a new better, stronger and yep more powerful engine began. Starting with the block of course that is either STD or 20 thou to give the poor head gasket space to seal. I found a good 20 thou block, only to discover.......

This is a prime example of what happens when you do not know what you are doing and have a "It will be fine, what is this crank end float BS that you are talking about on anyway....What do you know anyway about building a mini engine???????" bad attitude towards crank end float REALITY, thanks previous owner of THIS block for destroying a otherwise good block. The search continued.

Own some minis, break them, fix them, improve them, test them to the limit....

![[-]](https://samini.co.za/images/collapse.png) •

•

Posts: 185

Threads: 11

Likes Received: 20 in 17 posts

Likes Given: 13

Joined: Aug 2015

Reputation:

4

09-02-2020, 12:11 PM

(This post was last modified: 09-02-2020, 12:20 PM by Boyscout.)

Hi Philip,

looking at the picture it looks like you may have to get the block resurfaced again. I suggest you fit a proper BK450 black gasket. It is the best option for a 1275 and is superior to the copper gasket. Also be careful no to over torque the head bolts. This causes the fire-ring to collapse and cause failure. I also do not prescribe to re-torqueing. On my previous mini I torqued the head to the minimum torque spec when i built the motor and never touched the head bolts again. No issues.

I am busy overhauling the engine in my current Mini, a 998 A+. This engine has never been opened since '89 and the internals are in ok condition. However the primary gear endfloat was way out of spec as well is the idler gear. It was quite a mission to get within spec again. Crank end-float was on the upper end with new std thrust washers installed. But you are right, most people just slap new stuff on and don't check these important clearances.

Are the timing sprockets still ok? They look very worn on the picture.

![[-]](https://samini.co.za/images/collapse.png) •

•

Posts: 271

Threads: 28

Likes Received: 90 in 61 posts

Likes Given: 0

Joined: Aug 2015

Reputation:

2

Hi Boyscout

Did not have much of a choice with the timing of the engine rebuild, seeing as I did it during the most stringent part of lockdown, thus I had to use what was at hand ito the gears.

I did find a block to use in the end like stated before, did not want to re-use original block. For those in the know, yes it is no longer a GTS block.

Some broken bolt removal during prep phase.

After a line bore, skimm, bore and hone and refacing due to some WTF who knows what the previous owner did to this block.

Own some minis, break them, fix them, improve them, test them to the limit....

Posts: 271

Threads: 28

Likes Received: 90 in 61 posts

Likes Given: 0

Joined: Aug 2015

Reputation:

2

On with the build.

Cleaned up the block from all old paint.

All masked and ready for the engine enamel

Coming along nicely.

Own some minis, break them, fix them, improve them, test them to the limit....

![[-]](https://samini.co.za/images/collapse.png) •

•

Posts: 271

Threads: 28

Likes Received: 90 in 61 posts

Likes Given: 0

Joined: Aug 2015

Reputation:

2

Some time ago I did this so not in chronological order.

Like I stated earlier, more speed, more reliable, faster.....

LET THE MODS BEGIN

One of the many steps to change the crank.....

After many hours on the milling machine and lathe. The end result was well worth the effort and money. Now I had to have the whole rotating assembly balanced. I sent the crank, flywheel, backplate, clutch plate, diaphragm, timing gear and pulley for this. Some funds later I collected it. I did clean the block yesterday with parafin, then de-greaser so re-assembly will start in earnest.

Own some minis, break them, fix them, improve them, test them to the limit....

![[-]](https://samini.co.za/images/collapse.png) •

•

Posts: 271

Threads: 28

Likes Received: 90 in 61 posts

Likes Given: 0

Joined: Aug 2015

Reputation:

2

Back to the present.

Said crank getting threads cleaned before being cleaned itself.

Main caps taking a bath also.

Own some minis, break them, fix them, improve them, test them to the limit....

![[-]](https://samini.co.za/images/collapse.png) •

•

|

![[-]](https://samini.co.za/images/collapse.png)